Home » Block Making Machine

Block Making Machine

SMAT concrete block making machine can produce various high-strength wall blocks, hollow blocks, paving blocks and slope protection blocks etc. With our automated process, brick making machines can transform raw materials into high quality, consistent specification bricks. Until now, our block making machines have been widely used in construction, roads, bridges and other engineering projects by customers around the world.

Home » Block Making Machine

Block Making Machine

SMAT concrete block making machine can produce various high-strength wall blocks, hollow blocks, paving blocks and slope protection blocks etc. With our automated process, brick making machines can transform raw materials into high quality, consistent specification bricks. Until now, our block making machines have been widely used in construction, roads, bridges and other engineering projects by customers around the world.

SMAT concrete block-making machines can produce various high-strength wall blocks, hollow blocks, paving blocks slope protection blocks, etc. With our automated process, brick-making machines can transform raw materials into high-quality, consistent specification bricks. Until now, our block-making machines have been widely used in construction, roads, bridges, and other engineering projects by customers around the world.

Why Choose SMAT Bricks Making Machine:

Advanced Technology and Design:

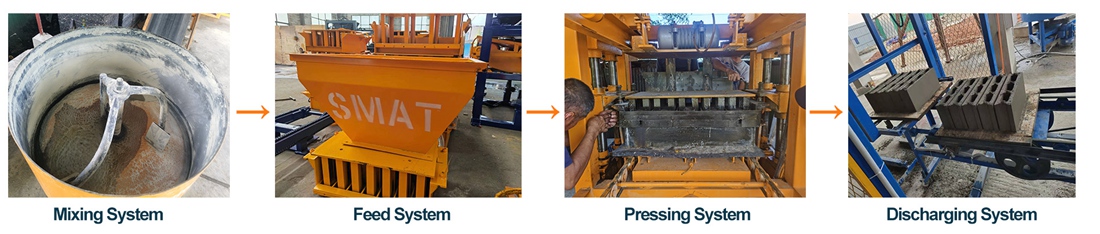

▶The concrete block machine adopts an efficient and super strong vibration system to ensure the density of the product.

▶SMAT concrete block-making machines can adapt to different types and specifications of bricks and have strong production adaptability. Electromagnetically, hydraulic, synchronous drive control, the same pallet product error is greatly reduced. Different raw materials can be adjusted accordingly to meet the needs of different projects.

▶The computer controls the materials to ensure uniform supply. The bricks have stable quality, consistent size, and smooth surface, complying with building standards. Advanced brick-making technology ensures the high strength and durability of the bricks. The automated control system makes the entire production process smoother and reduces manpower input.

Safety and Environmental Protection:

▶Use advanced production technology and energy-saving technology to reduce energy consumption and improve energy utilization. Achieve green and environmentally friendly production by reducing waste generation and optimizing the production process.

▶The equipment has a solid structure and uses high-quality materials and advanced manufacturing processes to improve the stability and durability of the equipment. Minimize failure rates, reduce maintenance costs, and ensure long-term reliable operation.

For customers:

▶High-quality quality block machines can produce bricks efficiently and quickly, improve production efficiency, and save costs.

▶Use advanced production technology and energy-saving technology to reduce energy consumption and improve energy utilization. Achieve green and environmentally friendly production by reducing waste generation and optimizing the production process.

▶The block-making machine is equipped with an intelligent control system, which is easy to operate and can be controlled through a touch screen or remote control. Operators do not need much professional knowledge and can quickly get started and improve production efficiency.

▶It can be equipped with a full-process monitoring system to monitor production status in real-time and provide early warning of potential problems. Provide remote technical support to reduce maintenance time and ensure continuous and stable operation of equipment.

▶Provide personalized customized services according to the specific needs of customers to meet the requirements of different projects. Flexible configuration options allow customers to choose suitable models and functions according to actual needs.

Factory Capability:

SMAT was established in 1988, specializing in one-stop service for design, R&D, production, sales, and installation of concrete machinery and mining machinery. From the first machine off the production line to today’s products all over the world, we always believe that providing high-quality products and timely efficient after-sales service is the key to business development.

Currently, SMAT has several production plants in China. The total area is 300,000 square meters with 28 perfect production lines. As a top manufacturer of machinery for the construction industry, SMAT focuses on making innovative technologies, manufacturing better quality products, and providing comprehensive solutions for the projects of our global customer partners. Our products have been exported to more than 80 countries and we have set up service stations in many countries.

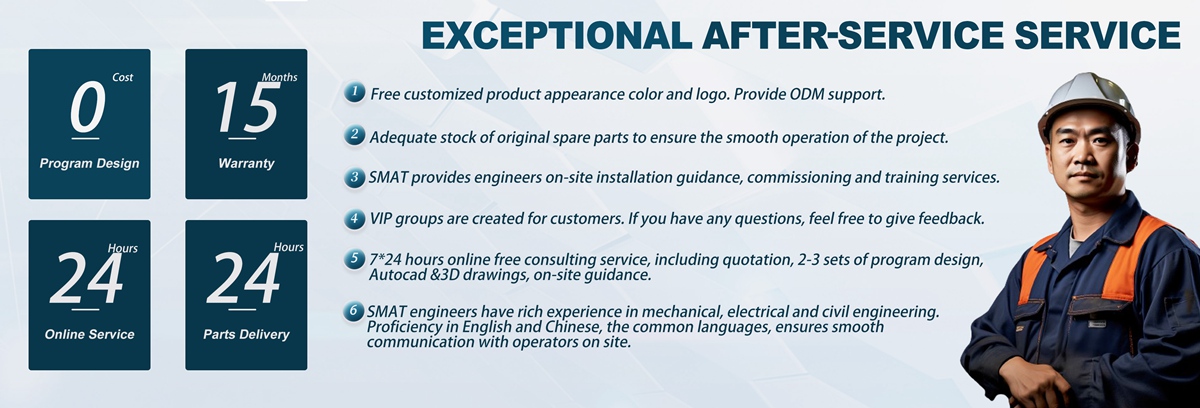

Online Service:

▶Free customized product appearance color and logo. provide ODM support.

▶Adequate stock of original spare parts to ensure the smooth operation of the project.

▶SMAT provides engineers with on-site installation guidance, commissioning, and training services.

▶VIP groups are created for customers. If you have any questions, feel free to give feedback.

▶7*24 hours online free consulting service, including quotation, 2-3 sets of program design, Autocad &3D drawings, and on-site guidance.

▶SMAT engineers have rich experience in mechanical, electrical, and civil engineering. Proficiency in English and Chinese, the common languages, ensures smooth communication with operators on site.