Home » Concrete Pumping Machine » Concrete Mixer Pump

Concrete Mixer Pump

>Max. Theo. concrete output: 30-40(m³/h)

>Max. concrete pumping pressure: 10MPa

>Diesel Engine Model: Weichai

>Electrical engineering power: 66-82KW

>Max. Theo. concrete output: 30-40(m³/h)

>Max. concrete pumping pressure: 10MPa

>Diesel Engine Model: Weichai

>Electrical engineering power: 66-82KW

SMAT, as a top manufacturer of construction industry machinery, focuses on innovative technology to manufacture better quality concrete mixer pumps. Dedicated to providing comprehensive solutions for our global customer partners’ projects.

SMAT has diesel-type and electric-type concrete mixer pumps. According to the category of pumps, there are four main types, which are trailer pump, mixer pump, boom pump, and truck-mounted pump. We can make the corresponding program according to the customer’s demand for the flow rate, pressure, and mixing capacity of the product. The actual vertical height of pumped concrete can reach 80-100 meters and the horizontal distance is 150-300 meters.

Diesel Concrete Mixing Pump

| Max. Output(L./H) | 30m³/h | 40m³/h |

|---|---|---|

| Max. pump pressure(H./L.) | 10MPa | 10MPa |

| engine model | Weichai | Weichai |

| Max. agg. diameter | Slick/scree:10/20mm | Slick/scree:40/50mm |

| Dimensions: | 4500x1750x1600 | 600x2300x3150 |

| weight(kg) | 3000 | 4500 |

Electric Concrete Mixing Pump

| Max. Output | 30(m³/h) | 40(m³/h) |

|---|---|---|

| Max. Pump pressure | 10(MPa) | 10(MPa) |

| Power | 37(KW) | 45(KW) |

| Max. agg. diameter | Slick/scree:10/20(MM) | Slick/scree:40/50(MM) |

| Dimensions: | 4500x1750x1600(MM) | 4200x2300x3150(MM) |

| Weight | 3000(kg) | 4500(kg) |

Why Choose SMAT Concrete Pumping Machine:

Advanced Technology :

▶SMAT uses the world-famous brand drive motor, more stable quality, and longer service life.

▶We adopt double pumps and double-circuit open hydraulic systems. The main pump oil circuit and S-valve swing oil circuit are independent of each other, so it is easy to determine the source of failure and eliminate it in time.

▶The reverse state is conducive to troubleshooting pipe blockage and can stop running for a short time to wait for materials. It also helps to prolong the service life of the pumping machine.

▶Advanced S distribution valve can automatically make up for the wear gap and good sealing performance.

▶It has an automatic enhanced lubrication system to ensure effective lubrication during operation.

▶The cooling system adopts a forced air-cooled radiator device to ensure that the working oil temperature is below 70 ℃, which ensures that the hydraulic system of the host is in normal working condition.

▶ If your area has enough electricity and stable voltage. We offer both fuel and pure electric models.

For customers:

▶Choose SMAT stable performance and high-quality concrete mixer pump, the failure rate is very low and the return rate is greatly improved. It can mix and deliver ready-mixed concrete quickly, saving time and labor costs.

▶Ensure the proportion of concrete mixture accuracy in every batch, reducing the high cost of trial and error.

▶The convenience of the SMAT concrete mixer pump helps you make quick progress on your project at the site. Save a lot of labor and expense to transport concrete to the site.

▶Wireless remote control operation is more safe and more convenient for operators. With the automated control system as well as intelligent operation, it can save time for training.

▶For SMAT concrete mixer pump, less investment, higher quality concrete, which can help buyers take the investment back within a short time. Both reduce the impact on the environment and save costs.

Factory Capability:

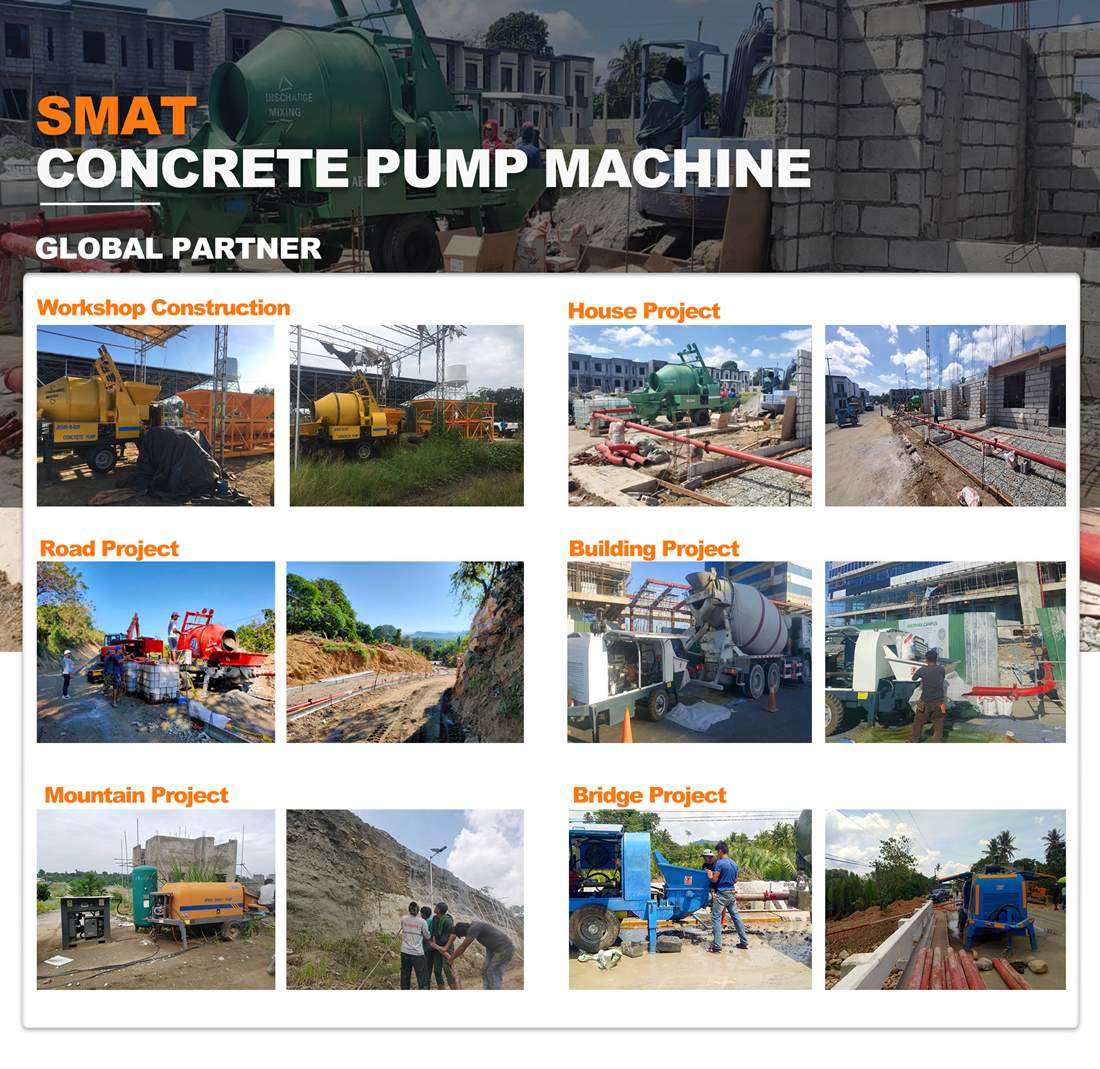

SMAT was established in 1988, specializing in one-stop service for design, R&D, production, sales, and installation of concrete machinery and mining machinery. From the first machine off the production line to today’s products all over the world, we always believe that providing high-quality products and timely efficient after-sales service is the key to business development.

Currently, SMAT has several production plants in China. The total area is 300,000 square meters with 28 perfect production lines. As a top manufacturer of machinery for the construction industry, SMAT focuses on making innovative technologies, manufacturing better quality products, and providing comprehensive solutions for the projects of our global customer partners. Our products have been exported to more than 80 countries and we have set up service stations in many countries.

SMAT Concrete Batching Plant Partner Strength:

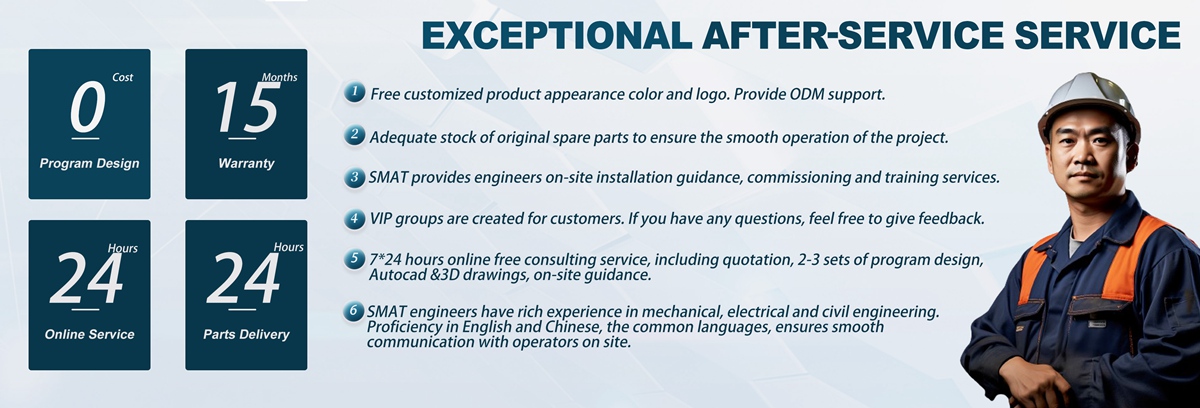

Online Service:

▶Free customized product appearance color and logo. provide ODM support.

▶Adequate stock of original spare parts to ensure the smooth operation of the project.

▶SMAT provides engineers with on-site installation guidance, commissioning, and training services.

▶VIP groups are created for customers. If you have any questions, feel free to give feedback.

▶7*24 hours online free consulting service, including quotation, 2-3 sets of program design, Autocad &3D drawings, and on-site guidance.

▶SMAT engineers have rich experience in mechanical, electrical, and civil engineering. Proficiency in English and Chinese, the common languages, ensures smooth communication with operators on site.