Home » Crushing Machine » Impact Crusher

Impact Crusher

Home » Crushing Machine » Impact Crusher

Impact Crusher

10-500 tons per hour.

Suitable for middle hard material, Granite, waste concrete, limestone, etc.

Easy discharge size adjustment

Self protection, no worry iron.

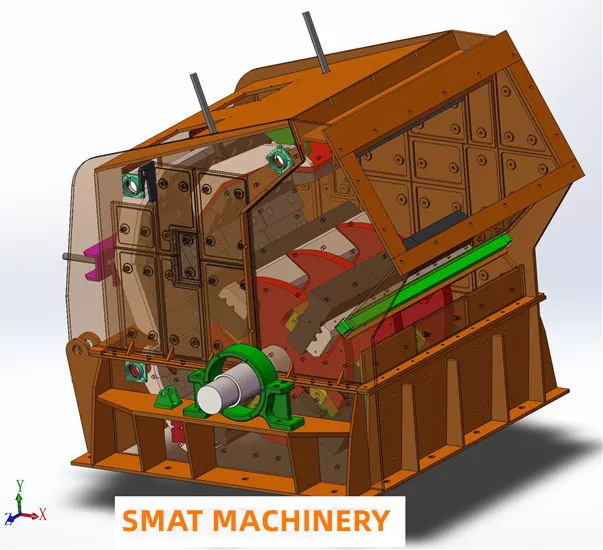

The impact crusher adopts new manufacturing technology and unique structural design. The finished product is cubic, without tension and cracks, and the particle shape is quite good. Coarse, medium and fine material ore, rock (granite, limestone, concrete, etc.), widely used in hydropower, highway, artificial sand and gravel, crushing and other industries.

The impact crusher produced by our company has a unique structure, is equipped with a high-chromium blow hammer, and has a unique impact lining plate; it is suitable for hard rock crushing; the size of the discharge is adjustable, which can simplify the crushing process, and has the advantages of large crushing ratio, high crushing efficiency, cubic shape products and so on.

Working principle of impact crusher

Impact crusher is a crushing machine that uses impact energy to crush materials.

When the machine is working, driven by the motor, The rotor rotates at a high speed, when the material enters the blow bar action area, it collides with the blow bar on the rotor and is broken, and then is thrown to the impact plate to be broken again, and then bounces from the impact plate liner back to the blow bar action area to be broken again. The process is repeated, and the material enters the first, second and third crushing chambers from large to small for repeated crushing, until the material is crushed to the required particle size and discharged from the discharge port.

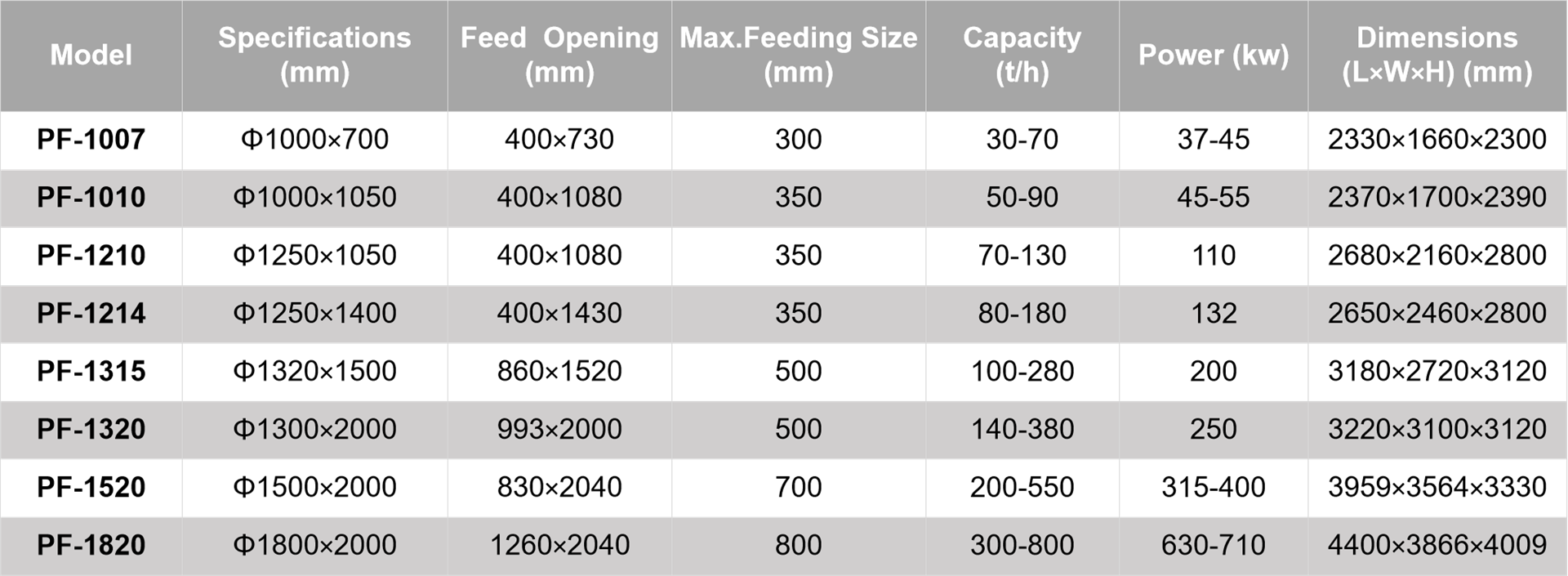

| Model | Specifications (mm) | Feed Opening (mm) | Max.Feeding Size (mm) | Capacity (t/h) | Power (kw) | Dimensions(L×W×H) (mm) |

|---|---|---|---|---|---|---|

| PF-1007 | Φ1000×700 | 400×730 | 300 | 30-70 | 4P 37-45 | 2330×1660×2300 |

| PF-1010 | Φ1000×1050 | 400×1080 | 350 | 50-90 | 4P 45-55 | 2370×1700×2390 |

| PF-1210 | Φ1250×1050 | 400×1080 | 350 | 70-130 | 6P 110 | 2680×2160×2800 |

| PF-1214 | Φ1250×1400 | 400×1430 | 350 | 80-180 | 6P 132 | 2650×2460×2800 |

| PF-1315 | Φ1320×1500 | 860×1520 | 500 | 100-280 | 6P 200 | 3180×2720×3120 |

| PF-1320 | Φ1300×2000 | 993×2000 | 500 | 140-380 | 6P 250 | 3220×3100×3120 |

| PF-1520 | Φ1500×2000 | 830×2040 | 700 | 200-550 | 4P 315-400 | 3959×3564×3330 |

| PF-1820 | Φ1800×2000 | 1260×2040 | 800 | 300-800 | 6P 630-710 | 4400×3866×4009 |

Why SMAT impact crusher so popular?

It is convenient and flexible to adjust the discharge particle size, and the adjustment range is wide: the impact crusher can adjust the discharge particle size in various ways, such as adjusting the rotor speed, adjusting the gap between the impact plate and the crushing chamber, etc.

The wear of the blow bar occurs only on the side facing the material. When the rotor speed is normal, the feed will fall to the surface of the blow bar, and the back and sides of the blow bar will not be worn. There is also very little wear on the side facing the material. The metal utilization rate of the impact crusher plate hammer can be as high as 45%-48%.

The blow bars can be replaced easily, and it only takes one shift to replace a set of blow bars. The cost of downtime maintenance time is greatly saved.

High chrome blow bar, impact resistance, wear resistance and high impact force;

Keyless connection, easy maintenance, economical and reliable.

It has a selective crushing effect, and the particle size of the crushed products is relatively uniform, and most of the shapes are cubic stones. It has a wide range of applications for bridge construction, high-speed road construction, docks, and airport construction.

Q:Several important tips for impact crusher running and maintenance.

- After stopping the feeding, let the crusher continue to run until the remaining materials in the crushing chamber are processed.

- When the equipment is stopped, first cut off the working power.

- After the impact crusher is stopped, the discharge conveyor can be stopped until the material on the discharge conveyor has been conveyed.

- After the motor is repaired or rewired, it is recommended to carefully check the correctness of the direction to ensure that the equipment rotates in the specified direction, and it is strictly forbidden to run in the opposite direction.

- If the equipment is stopped due to the excessive particle size of the crushed material, the user should check the wear of the plate hammer after stopping to prevent the rotor from being worn out.

- If the equipment is stopped due to serious wear of the blow bars, when the user adjusts the blow bars 180° to use again, they should make the weight of each blow bar equal and keep it balanced to prevent vibration after starting.

Q:Can we use impact crusher to crush high moisture material?

Yes, impact crusher is suitable for high moisture crushing. Due to it’s special structure, no need to worry about chamber blocking issue.

Q:Can we use impact crusher to crush waste concrete?

Yes, impact crusher is suitable for waste concrete crushing.

Q:How to choose suitable impact crusher?

Impact crusher normally used as secondary crushing equipment. Which means, it will work with other equipment, like jaw crusher, vibrating screen, etc. We have engineer team specially for project solution designing, they will calculate based on your project requirement, such as the hourly capacity, input and output size, etc. Please contact us for free project designing.

Q:Can the impact crusher be equipped with diesel engine or generator?

We offer customized equipment. If there is no stable electricity supply, we will suggest you to use diesel generator. And the detailed solution can be designed per your project requirement.

Q:How can we check your machine quality?

We can have video conference with your team, thus we can show you our workshop and machine quality.

On the other hand, we accept third party inspection.

Q:How can you ensure your after sale service during the pandemic?

- We have professional engineers can provide both online and on-site installation and training.

- We have local installation team partners can provide you turn-key installation, commissioning and training.