Global Case

Global Cases

Kenya is a country with rapid infrastructure development, and has

The Sri Lankan customer purchased the concrete mixing plant for

Bangladeshi customers are very sensitive to machine quality and price.

Due to the large number of islands in the Philippines,

The concrete trailer pump can be used in various projects

The 4m3 self-loading concrete mixer truck adopts the overall frame,

This diesel trailer pump is used in high-rise buildings with

Indonesian customers came to China for suppliers inspection before purchasing

For small and medium-sized projects, such as: concrete roads, houses,

The service life of concrete batching plant is very long.

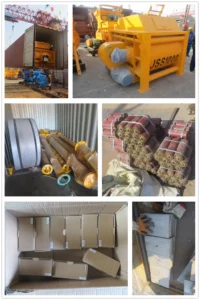

Many customers will purchase some supporting equipment at the same

The Aggregates batching machine adopts a separate weighing system with

Kenya is a country with rapid infrastructure development, and has

For small and medium-sized projects, the cost of purchasing a

For small and medium-sized projects, the cost of purchasing a

It is the first time for this Kenyan customer to

Mobile batching plant is very popular in overseas markets, since

The asphalt mixing plant is mainly used to produce asphalt

The asphalt mixing plant is mainly used to produce asphalt