Home » Briquette Machine

Briquette Machine

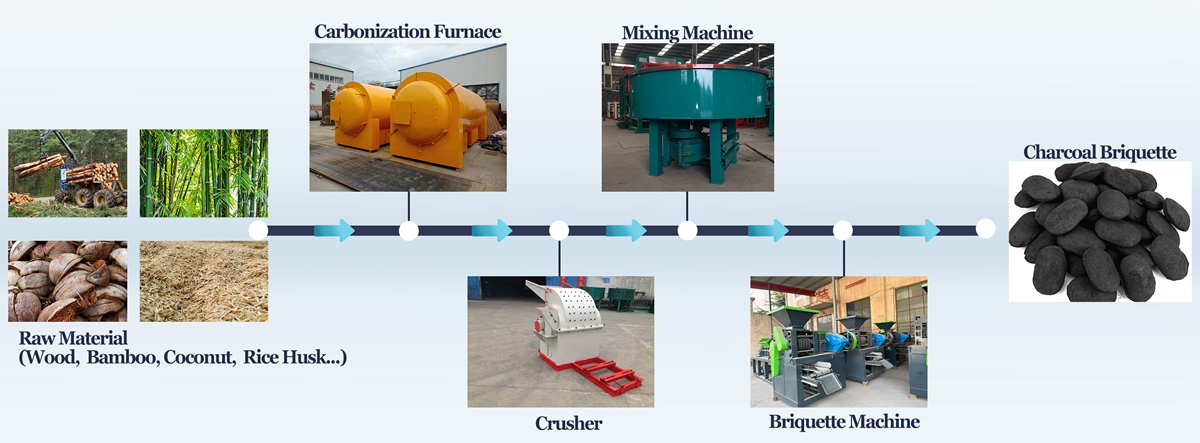

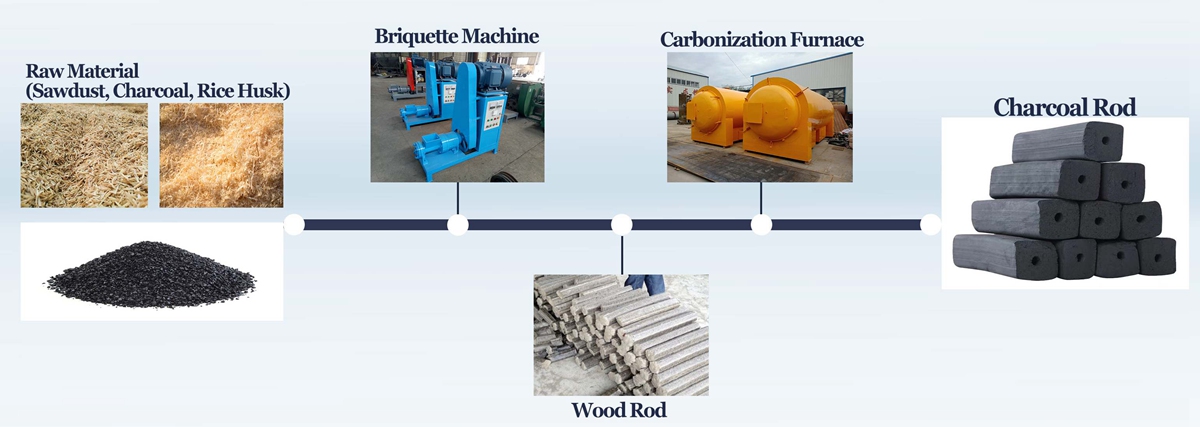

SMAT has advanced technology and process, no matter you need to charcoal briquettes from wood, bamboo, coconut, etc., or press wood chips, rice husk, etc., directly to make combustion rods, SMAT has the confidence to provide you with free design service and program support.

Home » Briquette Machine

Briquette Machine

SMAT has advanced technology and process, no matter you need to charcoal briquettes from wood, bamboo, coconut, etc., or press wood chips, rice husk, etc., directly to make combustion rods, SMAT has the confidence to provide you with free design service and program support.

SMAT provides one-stop service for customized briquette production lines. With good reputation, our customers are all over the world, and our products are widely used in refractories, power plants, metallurgy, chemical industry, energy, transportation, require, etc. SMAT has advanced technology and processes, no matter you need to charcoal briquettes from wood, bamboo, coconut, etc., or press wood chips, rice husk, etc., directly to make combustion rods, SMAT has the confidence to provide you with free design service and program support.

| Model | SMQ290 | SMQ360 | SMQ430 | SMQ500 | SMQ650 | SMQ750 | SMQ850 | SMQ1000 |

|---|---|---|---|---|---|---|---|---|

| Roller Diameter | 290mm | 360mm | 430mm | 500mm | 650mm | 750mm | 850mm | 1000mm |

| Capacity (t/h) | 1-2.5 | 3-4 | 4-5 | 5-6 | 9-10 | 13-15 | 19-25 | 28-30 |

| Motor Power (KW) | 5.5 | 7.5 | 15 | 37 | 37-45 | 45 | 55 | 90 |

| Dimension (mm) | 1700*1200*1400 | 1700*1400*1600 | 1900*1500*2000 | 2000*2000*2300 | 2800*2380*2460 | 2800*2500*2600 | 3000*2500*2600 | 3200*2600*3000 |

| Weight (kgs) | 900 | 1500 | 4500 | 7000 | 7800 | 10500 | 16000 | 20000 |

Plan A: If you have a lot of natural raw materials, consider this option.

Plan B: If you have a lot of Rice Husk or Sawdust, consider this option.

Why Choose SMAT Briquette Production Machine:

▶SMAT provides customized solutions for various raw materials, finished product sizes, and shapes. Our engineers have rich design experience as well as on-site work experience and can rationalize the design according to your needs and working site.

▶Advanced technology and processes can ensure that every machine in every plan can minimize energy consumption and improve production efficiency.

▶The structure of the production line from raw material to finished product is simple, easier to start compared with traditional machines, and requires less maintenance work.

▶It is suitable for pressing many kinds of raw materials, including coal, ore, powdery materials, etc., which can meet the production needs of different industries and fields. Many successful project cases are for your reference, and make sure your projects are one of the successful ones also.

▶SMAT attaches importance to the feedback information from customers and takes this feedback information as the basis and direction of equipment improvement. From the appearance of the equipment, the overall structure, the quality of the motor and reducer, the material of the bearings, molds, paint, etc., we always pay attention to every detail and strive for perfection.

After-Sales Service:

▶Free customized product appearance color and logo. provide ODM support.

▶Adequate stock of original spare parts to ensure the smooth operation of the project.

▶SMAT provides engineers with on-site installation guidance, commissioning, and training services.

▶VIP groups are created for customers. If you have any questions, feel free to give feedback.

▶7*24 hours online free consulting service, including quotation, 2-3 sets of program design, Autocad &3D drawings, and on-site guidance.

▶SMAT engineers have rich experience in mechanical, electrical, and civil engineering. Proficiency in English and Chinese, the common languages, ensures smooth communication with operators on site.