Home » Concrete Batching Plant » Mobile Concrete Batching Plant

Mobile Concrete Batching Plant

>Theoretical Productivity: 25-90(m³/h)

>Mixer Discharging Volume: 500-1500L

>Discharging Height: 3.8-4.1M

>Installation Power: 65-140KW

>Theoretical Productivity: 25-90(m³/h)

>Mixer Discharging Volume: 500-1500L

>Discharging Height: 3.8-4.1M

>Installation Power: 65-140KW

SMAT concrete batching plant is a mechanized, automated, high-efficiency, and integrated concrete mixing equipment that is widely used in concrete production projects with large quantities of work and long construction periods. SMAT has successfully exported to more than 80 countries with our technological innovation and R&D strength in the field of concrete machinery, as well as the high performance and versatility of products.

Why Choose SMAT Concrete Batching Plant:

Advanced Technology and Design:

▶SMAT concrete batching plant introduces advanced mixing technology and is equipped with an efficient mixing system to ensure uniform and stable quality of concrete. It has high production efficiency, strong mixing ability, and strong flexibility.

▶SMAT has an exclusive patented energy-saving design and is equipped with a wastewater treatment system and a noise treatment system to reduce energy consumption.

▶There are complete types of equipment, and the configuration options can fully meet user needs and adapt to installation in different areas. Suitable for various special concrete production. Dry hard concrete, semi-dry hard concrete, plastic concrete, fluid concrete, etc.

Choice of Materials:

▶Use wear-resistant materials. The support frame and aggregate bin are designed to be strong and durable for longer service life. The structural design is reasonable and the maintenance is gradual. Reduce downtime and increase production efficiency.

Intelligent Production:

▶Equipped with an automated control system, it can realize fully automatic production operations, improve production efficiency, and reduce labor costs.

▶Adopt modular design and easy installation. It can be customized according to engineering needs to improve the adaptability and flexibility of the equipment.In case machine parts fail, regional debugging can be used to solve the problem and avoid time costs.

▶Use an imported lubrication system and shaft drive system. All components have reliable quality and stable performance.

▶Equipped with an intelligent management system to realize real-time monitoring and data analysis of the production process. It helps to adjust production parameters in time and improve production efficiency.

Safety and Environmental Protection:

▶The production process is environmentally friendly, with no noise, and no dust. The cleaning system uses automatic control and manual control of high-pressure water pumps.

Factory Capability:

SMAT was established in 1988, specializing in one-stop service for design, R&D, production, sales, and installation of concrete machinery and mining machinery. From the first machine off the production line to today’s products all over the world, we always believe that providing high-quality products and timely efficient after-sales service is the key to business development.

Currently, SMAT has several production plants in China. The total area is 300,000 square meters with 28 perfect production lines. As a top manufacturer of machinery for the construction industry, SMAT focuses on making innovative technologies, manufacturing better quality products, and providing comprehensive solutions for the projects of our global customer partners. Our products have been exported to more than 80 countries and we have set up service stations in many countries.

SMAT has various types of concrete batching plants. Provide customized options based on your demands capacity, mixing efficiency, feeding speed, etc. These include mobile concrete batching plants, stationary concrete batching plants, belt feeding type concrete batching plants, twin shafts concrete batching plants, and vertical type concrete batching plants.

Mobile Concrete Batching Plant

| Parameters/Model | YHZS-25 | YHZS-35 | YHZS-60 | YHZS-90 |

|---|---|---|---|---|

| Productivity | 25(m³/h) | 35(m³/h) | 60(m³/h) | 90(m³/h) |

| Discharging Volume | 500L | 750L | 1000L | 1500L |

| Discharging Height | 3.8(m) | 4.1(m) | 4.1(m) | 4.1(m) |

| Power | ≈65 (KW) | ≈75 (KW) | ≈100 (KW) | ≈140 (KW) |

Online Service:

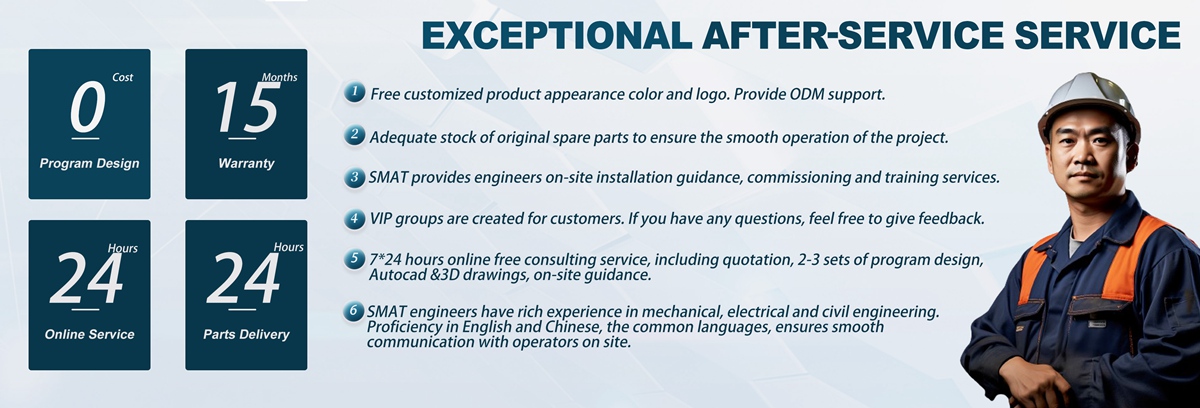

▶Free customized product appearance color and logo. provide ODM support.

▶Adequate stock of original spare parts to ensure the smooth operation of the project.

▶SMAT provides engineers with on-site installation guidance, commissioning, and training services.

▶VIP groups are created for customers. If you have any questions, feel free to give feedback.

▶7*24 hours online free consulting service, including quotation, 2-3 sets of program design, Autocad &3D drawings, and on-site guidance.

▶SMAT engineers have rich experience in mechanical, electrical, and civil engineering. Proficiency in English and Chinese, the common languages, ensures smooth communication with operators on site.