Looking to buy a briquette making machine? You’ve come to the right place! In this guide, we will discuss everything you need to know before making your purchase. We’ll talk about the different types of briquette machines available, as well as the features you should look for when making your decision. By the end of this guide, you’ll be able to make an informed decision and buy the perfect briquette making machine for your business!

What is a briquette making machine?

A briquette press machine is a device that takes raw materials like paper pulp, sawdust, and other scraps of organic material and compresses them into solid briquettes. Through the use of pressure, temperature, and mechanical force, these machines are able to transform waste material into something far more useful.

Briquettes’ applications are producing fuel for homes or businesses that rely on burning biomass materials or burnable blocks to produce heat and energy. For example, in many rural areas in developing countries where wood is scarce, briquette press machines can create an affordable alternative for local inhabitants who rely heavily on wood as their primary source of fuel.

Thanks to advances in technology and engineering, these machines are capable of delivering highly efficient results when it comes to producing quality briquettes that provide maximum combustion efficiency and minimal smoke.

What types of briquette machines are available?

There are several different types of briquette machines to choose from, including manual and automatic options:

1. Manual briquette press machine

This is the most affordable option and can be used with a hand crank or motor. It’s best suitable for smaller operations.

2. Automatic briquette press machine

This type of machine is aumatic and more expensive than the manual option. It’s best for larger operations with a high production rate.

How does a briquette making machine work?

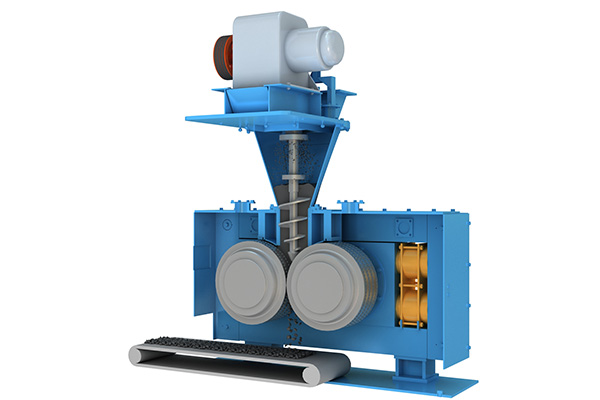

Briquette machines essentially use an efficient production process to turn various materials such as wood, coal, and even plastic into small compressed briquettes. The machines can compress the raw material with a set amount of force, making it easier to form into a shape. They also often contain heating elements so that the binding agents bind together better. This helps make the briquettes strong and they also hold their shape as they cool.

In operation, the machine pushes the material down through a die which has special embossed patterns that help give the briquettes their shape. Typically, these patterns are cylindrical in shape so that the briquettes can more effectively stack for storage and transport. Additionally, this machine process creates minimal wastage since what’s left of the briquette is mostly dust particles or small crumbs that can be reused in other applications.

What is the use of a briquette making machine?

Briquette press machines offer an efficient and low-cost solution for producing quality briquettes. They are capable of transforming a wide variety of materials into useful fuel products that are suitable for domestic, commercial, and industrial use.

- First, briquette press machines enable manufacturers to transform biomass into high-density cylindrical briquets. These briquets have higher efficiency and burn longer than conventional fuels like firewood, thus providing an economical and practical alternative to traditional sources of energy.

- Additionally, these machines can produce industrial-strength briquettes with consistent shapes and sizes, making them difficult to break.

- Furthermore, they offer good heat output; thus creating ideal conditions for burning in both indoor and outdoor areas.

What features should you look for when buying a briquette making machine?

- 1. Durability: Look for a briquette press that is made from durable materials such as stainless steel to ensure it lasts a long time.

- 2. Size: Consider the size of your operation and make sure you get a machine that is suitable for it.

- 3. Cost: The cost of the briquette machine can vary greatly depending on the size and features, so make sure you do your research to find one within your budget.

- 4. Efficiency: Look for a machine that is energy efficient and produces high-quality briquettes quickly and with minimal waste.

SMAT Brand briquette machine is a cutting-edge piece of technology designed to manufacture high-quality pressed and shaped briquettes from various different materials. With its ability to work with a wide range of materials, it removes limitations that other types of machines present and offers immense flexibility.

Second, these products can be tailored to the specifications needed by each individual customer in terms of size and shape. Furthermore, this briquette making machine can provide convenient operation, excellent results, and lasting value.

Now that you know more about low-cost briquetting machines, it’s time to start shopping! Please view https://www.smatmachinery.com/briquette-machine/ fore more information.